|

|

|

The "Glass Bead" IncidentBy Donna SpeidelEarlier this year, Sightline was hired by an insurance carrier to conduct an investigation into an incident involving a new aircraft that had picked up strange, sparkly things on its new tires. Those things that glittered were glass beads that had been picked up on the airplane's tires when it taxied through newly painted taxiway lines at the airport. A great deal of anxiety, expense, finger pointing and claims ensued, as the aircraft manufacturer believed that the glass beads had been sucked up into the engine and had done some damage. Our task was to determine how those errant glass beads had found their way onto and into the aircraft. If correctly anchored in the paint, glass beads won't come loose. Ah, but therein lay the problem. As is often the case, a painter had been hired by the airport to apply the markings to the airfield pavements. Having had some experience painting parking lots, he was given a paint machine, a manual for the equipment, various helpers; and was charged with the responsibility of refreshing the markings when so directed. There was little training provided, as his predecessor had left the airport's employ a few months earlier and was unavailable to return to train his successor. And so it goes.

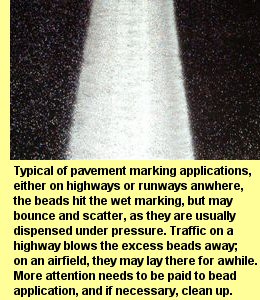

Sightline traveled to the airport and began its investigation into the cause of the mishap. The findings were typical of painting operations at airports all around the world; it's just this time, "all the stars and planets lined up perfectly," as the County's Risk Management Officer pointed out, and they got caught. Although, in the end, it was determined there was no damage to the jet engines, it all created quite a stir. There was even a comment that glass beads should no longer be used. But that's kind of like "throwing the baby out with the bath water". They provide a significant measure of safety on traveled pavements everywhere, including airports. The right answer is to pay attention to the details of applying them and doing diligent clean up if necessary. A representative of the Air Force Civil Engineering Agency (AFCESA) issued a directive to base engineering offices that sweeping airfield pavements after a marking operation would be a prudent measure to better insure the safety of USAF aircraft and personnel.

Sightline provided training to the maintenance staff, particularly the painter and his supervisor. We returned one month later to oversee the painting operation when the airport wanted to restore the problem taxiway to use. More training was provided, along with simple tools for adjusting the paint thickness and monitoring the glass bead flow and usage. The maintenance staff, intent on doing well, was "getting it" and becoming quite proficient in a short time. As the claims adjuster from the insurance company, our employer during the investigation, stated:

"The problems that you identified during this claim, and the follow-up remedial

measures that you applied, are certainly important to the whole industry. I think

it is extremely important that all Airport Operators understand the implications of

failure to properly perform these types of operations. As we both know, the FAA has

published the minimum standards for application of the paint and beads, in the form

of an Advisory Circular. As with any document such as this, the information means

nothing, if the people applying the product are not fully aware of the necessity of

following these minimum standards. In my mind, that is where you can help the most.

I have to believe that there are many Airport Operators that would find a review of

their policies and procedures regarding these types of operations, as a beneficial

result of what we have learned by our experience..."

|

What seemed like a simple task of applying paint to pavement turned into a major

claim, the reason for which can only be described as well-intentioned ignorance. No one knew any

better. No one ever dreamed that simply loading paint and glass beads into the machine and

repainting the markings would turn into such an ordeal. But it did; it does, and it can.

What seemed like a simple task of applying paint to pavement turned into a major

claim, the reason for which can only be described as well-intentioned ignorance. No one knew any

better. No one ever dreamed that simply loading paint and glass beads into the machine and

repainting the markings would turn into such an ordeal. But it did; it does, and it can.

The fact is: none of this is uncommon! Additionally, almost any airport that

engages in pavement marking operations, either with its own maintenance personnel or with hired

contractors, has problems with poorly bonded paint, multiple layers, cracking of both paint and

pavement, and the potential for foreign object damage (FOD). There is considerably more involved than

loading paint and glass beads into a machine, turning on the paint guns and following the old lines.

But that's what most airport maintenance crews do; and frankly, what many painting contractors do as

well. Most are accustomed to painting parking lots and highways where that is the common practice.

But airfield markings are quite different.

(See article "

The fact is: none of this is uncommon! Additionally, almost any airport that

engages in pavement marking operations, either with its own maintenance personnel or with hired

contractors, has problems with poorly bonded paint, multiple layers, cracking of both paint and

pavement, and the potential for foreign object damage (FOD). There is considerably more involved than

loading paint and glass beads into a machine, turning on the paint guns and following the old lines.

But that's what most airport maintenance crews do; and frankly, what many painting contractors do as

well. Most are accustomed to painting parking lots and highways where that is the common practice.

But airfield markings are quite different.

(See article "