|

|

PrimetimeBy Mike Speidel

A little background: A runway extension added new asphalt surfaces to each runway end and the existing pavements had rejuvenator applied to them. The consulting engineer overseeing the project requested Sightline to provide quality control during the marking application after the 30-days had elapsed for the new pavements to cure. The engineer had enhanced its client's project specifications by including performance criteria for marking retroreflectivity, which we have discussed being a best practice in this very newsletter from time to time. The airport wanted Type III beads (the expensive ones) on this runway -- we were hired to make sure the airport was getting the return on their investment. The painting subcontractor and I got together in the morning of the first day and discussed what I was doing there and went over what my expectations were. Cooperating, the contractor and I calibrated his truck-mounted equipment and began to paint test lines. After several adjustments, I really liked the resulting test panel -- and I was confident the performance standards would be reached. The contractor, now armed with an understanding of what I was looking for, began to paint the permanent threshold markings. I took out my trusty LTL-X retroreflectometer and measured the test marking applied just 30 minutes before. Admittedly, reflectivity measurements are unreliable when taken inside 24 hours of installation, but in my experience, it gives you an idea of what to expect the following day -- and in hindsight, I'm really glad I decided to do it.

A six-reading average on a white marking with Type III beads yielded an average of 437 millicandelas (mcd). Based on what I was seeing on the test panels, I was expecting early readings closer to 600 mcd. I knew I had a problem. I pulled out my magnifying glass and got down on the ground to find the glass beads were hardly embedded in the paint -- the beads were practically sitting on top of the paint! I looked at the aluminum test panel again and bead embedment was perfect... It had to be the new pavement. I stopped the painting and called the consulting engineers over to recommended we try a primer coat on the new asphalt before painting permanent markings. The engineer agreed understanding the need to improve marking performance. With equipment, materials, application speed, and weather remaining constant, we painted test markings over 1) new, ungrooved, bare asphalt; 2) new, ungrooved, primed asphalt; and 3) old, grooved, rejuvenated asphalt. The results, although a small sample, were very interesting.

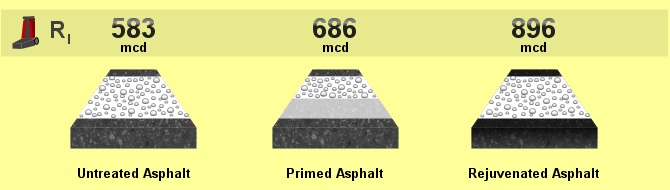

24 hours after application, using six-reading averages, the reflectivity (RI) measurements of permanent markings varied significantly depending on the qualities of the substrates. As illustrated above, reflectivity was lowest on new, bare asphalt; roughly 20% higher on new asphalt with a primer coating; and over 50% higher on bare, rejuvenated asphalt. Despite the small sample size, I wouldn't hesitate to recommend using a primer coat (230 SF/gal) without glass beads any time new asphalt requires permanent striping. It seems to act as a sealant which facilitates proper bead embedment during the permanent application, not to mention it may improve reflectivity and safety. Could your specifications use a review? We'll get your project ready for primetime, just email Mike. |

A recent Quality Assurance project dropped me right into what I now consider to have been a small-scale case study. Sightline

has recommended for some time now that new asphalt should receive a primer coat before permanent markings are installed. That is to say, a

half-rate coating (e.g. 230 SF/gal) without glass beads to assist in sealing the porous pavements. It's been recommended largely in theory to

this point, but I now have some compelling data to serve as a prime example as to why it could benefit your airport or client.

A recent Quality Assurance project dropped me right into what I now consider to have been a small-scale case study. Sightline

has recommended for some time now that new asphalt should receive a primer coat before permanent markings are installed. That is to say, a

half-rate coating (e.g. 230 SF/gal) without glass beads to assist in sealing the porous pavements. It's been recommended largely in theory to

this point, but I now have some compelling data to serve as a prime example as to why it could benefit your airport or client.