|

|

|

Much 'Ado' about "Nothing"Few of us notice traffic markings except for when they're not there. But Federal and State DOT's spend a lot of time and money making sure highways are well marked and visible to the traveling public. Airfield markings are no exception, but they are, relatively speaking, "out of sight" and unfortunately "out of mind". Airfield Marking Maintenance, quite possibly, is the most misunderstood child of our industry. The importance of the "incidental" components of airfield maintenance is lost on the majority of individuals that must deal with them. In an era so concerned with regulation and safety, more attention needs to be given to airfield markings. Never fear: Sightline is here. Have you ever had to repaint your house? What kind of things do you plan to do in order to perform the best job you can? Normally you must prepare the surfaces for painting: using scrapers or a pressure washer to remove old paint and perhaps priming the surface first before paint can be applied. It's good common sense to do so, and certainly worth the time. You're probably hoping that if you do a good job the first time, you can scratch it off the "to-do" list for several years. Since you don't want to repaint often, you're probably going to invest in a high-quality product, and follow the salesman's recommendation on how much to buy to cover the job. You buy the right equipment to apply the paint and go to work on the house. With the correct techniques and some elbow grease your house will come out looking great with a brand new finish! Contrary to popular belief, repainting an airfield is not different, with a couple exceptions. Glass beads are generally used in most airfield marking projects to increase visibility and provide safer environments for aircraft. Sightline does not recommend using glass beads on the exteriors of houses. We speak from experience: my house looks like a disco ball when cars go by. It is perhaps the only house that can be seen from space with the naked eye! Joking aside (for now), the equipment, materials, and techniques are different from those used for painting a house. However, the concept or approach to painting an airfield should be at least equivalent to that of your own house. The FAA, Air Force, Navy and Army Corps of Engineers have outlined a methodology in advisory circulars that should be followed to ensure your airfield is up to their standards. Quite frankly, Sightline recommends standards that surpass those - not to make brownie points, but to increase the life of your markings and to make your project more cost-efficient. You would do it for your own home, why not for that multi-million dollar airfield? There are several ways to make strides to get more bang for your buck. I will scratch the surface of some the issues: Training - many airports use their maintenance crews for painting, which represents a small portion of their responsibilities. Some are good, many are bad, and then there's the ugly: enough said. Each time the crews are called upon to repaint; they must learn the process and equipment all over again! Certification is required for lighting and signing, but not for airfield markings! Sightline believes the function provided by airfield markings is extremely important and should be maintained by trained, capable professionals. Train your crew to be airfield marking technicians. We can do that.

Writing accurate specifications - stating exactly what you need for your project is essential. Not only do you have to be familiar with your airfield's requirements, but you can get a very accurate idea of the material quantities and equipment needed to fulfill the contract precisely, whether doing the work with your own crews or soliciting bids from qualified contractors. We can help you with that, too.

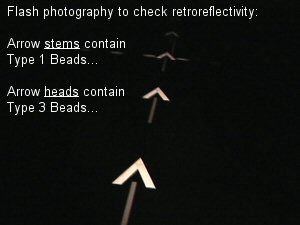

Quality Control - If you are going to invest the kind of money it takes to complete an airfield marking project, invest the time to inspect it. Make sure the job is done in accordance with FAA specifications as well as your own! Check the volumes of materials being applied as they are applied. Know where the markings belong and how the finished product should look. Tech Tip: Take the digital camera you got for Christmas out at night and use flash photography to evaluate the retroreflectivity of your markings. The idea here is that these guidelines aren't always followed. Often they're overlooked. (Remember the title of this dissertation?) That leads to the mother of all issues: LIABILITY. The FAA inspector might not reject your markings if they are a little out of tolerance here or there. However, suppose the airport suffers an incursion and a lawsuit ensues. The airport could be liable for anything a lawyer might find that might remotely have caused the incident. Trust us - it happens. Preventive maintenance is the best method to keep you out of the frying pan, and your airfield out of the fire. So much 'ado' about "nothing"? Most think so, but we're striving to change popular opinion (or even create an opinion!) Airport safety is important to all of us who travel, and airfield markings, although a small part of the overall picture, can make a BIG difference. Just in case some of you have made it through this diatribe: Sightline can train your personnel and/or provide the quality control to inspect markings during their application to ensure that your contract is being done in compliance with your standards that we can help you write. The saying goes, "You get what you pay for", but how do you know what you're getting if you don't know what to look for, or don't look at all?! We know you often don't have the time to watch paint dry, even if you know what to look for, but we do. It's not necessarily what you know, it's who you know. Fortunately, you now know Sightline. Visit us online at www.sightline.us. |

Materials - using inferior materials leads to an inferior project, common sense. Using the proper

materials and the correct application techniques will save you money in the long run. Paint on

runways doesn't behave like paint on highways, so why use the same materials? Glass beads are no different.

Type 1 beads for runways are less expensive, but don't provide the higher levels of nighttime visibility

needed for the higher speeds attained on the runway surface. Although Type 1 is fine for highways, Type 3

beads are a vastly superior product for use on airfield markings: easily seen in the picture on the right.

And standard traffic paints may not be right for runways. I'll save you the many reasons why, but will

say that in most cases Sightline recommends using the best products available to the

industry for your airfield.

Materials - using inferior materials leads to an inferior project, common sense. Using the proper

materials and the correct application techniques will save you money in the long run. Paint on

runways doesn't behave like paint on highways, so why use the same materials? Glass beads are no different.

Type 1 beads for runways are less expensive, but don't provide the higher levels of nighttime visibility

needed for the higher speeds attained on the runway surface. Although Type 1 is fine for highways, Type 3

beads are a vastly superior product for use on airfield markings: easily seen in the picture on the right.

And standard traffic paints may not be right for runways. I'll save you the many reasons why, but will

say that in most cases Sightline recommends using the best products available to the

industry for your airfield.

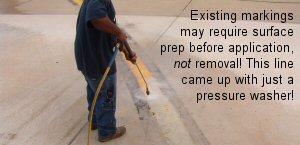

Surface Preparation (not necessarily paint removal) - horror films could be written depicting the

conditions we've seen painted over! I'm writing one now due out in a theater near you Labor Day

2007. A little alliteration: Preparing the surface previous to painting is a priority, or you will

repeat the repaint recurrently. We can help determine the right methods of preparation

or degree of paint removal needed.

Surface Preparation (not necessarily paint removal) - horror films could be written depicting the

conditions we've seen painted over! I'm writing one now due out in a theater near you Labor Day

2007. A little alliteration: Preparing the surface previous to painting is a priority, or you will

repeat the repaint recurrently. We can help determine the right methods of preparation

or degree of paint removal needed.