|

|

|

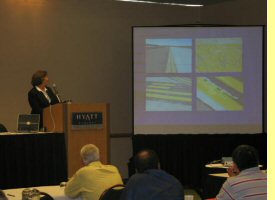

Education vs. CertificationBy Donna SpeidelWe have touched upon the concept of training before. It is certainly not a new concept to any industry; and when done effectively, the performance of those trained generally improves. Some state Departments of Transportation have not only implemented certification training for contract and state pavement marking crews, but many have also enforced performance specifications to the end product, intended to make the marking contractor accountable for the marking for a predetermined amount of time. The net result has been improved performance of highway markings wherever this process has been enforced.

Our experience has been that the airport personnel knew how to operate the equipment reasonably well. What they lacked were the details of the application process, e.g., paint thickness and how to measure, glass bead population and how to calibrate bead guns, limitations due to weather conditions, etc. Yet these are the details that make a marking project look good or bad, last 3 years or last 6 months. Enforcement of Specifications:Part of the issue of poor performance with airfield markings is a lack of proper enforcement of project specifications. Inspectors on a project often have a lot of other duties and assume the airfield marking crew knows what they are doing. Sometimes that is true, but sometimes it isn't. There are many aspects of a marking operation that need to be observed for quality control issues. And if the airfield marking crew is not already trained (even if they have 25 years of experience), there is a lot that can go wrong without anyone noticing. Then combine that with airfield maintenance or management not knowing what to look for, and you begin to get a vicious cycle of marking projects that compound the problems without regard to quality, longevity of the project, or a worsening condition of the pavement. Airports that are in the habit of painting everything every year may be able to save time and money by having their markings evaluated. Not all poorly performing markings need more paint. In fact, applying more paint may be contributing to the problem. Sightline personnel can help evaluate your markings, can design an airfield marking project that would include specifications specific to the project. Clear expectations and effective inspection should lead to a job well done; a win-win for everyone! |

Highway markings and airfield markings have similarities in their application, from equipment

and materials to working conditions. BUT, there is so much dissimilarity that differentiated training for those

marking contractors or airfield personnel involved in applying paint to airfield pavement should be required. What

is the difference between being "educated" and being "certified"? One can know what to do but not follow the

procedures for many reasons. If one is "trained" and subsequently "certified", one can be held accountable for the

end result, provided it is clearly defined and enforced.

Highway markings and airfield markings have similarities in their application, from equipment

and materials to working conditions. BUT, there is so much dissimilarity that differentiated training for those

marking contractors or airfield personnel involved in applying paint to airfield pavement should be required. What

is the difference between being "educated" and being "certified"? One can know what to do but not follow the

procedures for many reasons. If one is "trained" and subsequently "certified", one can be held accountable for the

end result, provided it is clearly defined and enforced.

We have provided training for airport personnel charged with applying the markings, and we

have trained consulting engineers and inspectors in what to look for when overseeing a marking project. The

normal response is that "we didn't realize how much there is to know about airfield markings!"

We have provided training for airport personnel charged with applying the markings, and we

have trained consulting engineers and inspectors in what to look for when overseeing a marking project. The

normal response is that "we didn't realize how much there is to know about airfield markings!"