|

Back to Webletter

FAA AC 150/5370-10G

By Donna Speidel

Connect with Donna

Connect with Donna

The most recent edition of the FAA Advisory Circular 150/5370-10 was released on July 21, 2014. The AC 5370-10G, Item P-620

"Runway and Taxiway Painting", has undergone extensive revision to include several quality control measures for new construction projects.

I'm comfortable with most of these items being included in your specifications as they're written, with some exceptions. To hear about all

of the changes, register for my pavement

markings webinar presented by the Airport Consultants Council on June 5th from 1230-130 EST.

This series of articles will address each change in the guidance literature, its intent, and what the new language means to you.

You may download your own copy of Item P-620 from our website as a reference by clicking on the icon to the right. Be sure to

share this article with your Resident/Consulting Engineers, a lot of the new language falls into their purview.

This series of articles will address each change in the guidance literature, its intent, and what the new language means to you.

You may download your own copy of Item P-620 from our website as a reference by clicking on the icon to the right. Be sure to

share this article with your Resident/Consulting Engineers, a lot of the new language falls into their purview.

620-2.3 – Reflective Media

1) TT-B-1325D, Type I

- What Changed - Added the following performance criteria: "should yield at least 300 mcd/m²/lux on white markings at installation and

at least 175 mcd/m²/lux on yellow markings at installation". Added that Type I "shall be used when remarking on a frequent basis (at least every

six months)".

- The Intent - To establish measurable performance requirements for Type I reflective markings at installation on new construction projects. Requires

applying the less expensive Type I bead when painting frequency is very high.

- What It Means To You - This language gives painting contractors performance criteria to meet or exceed on new construction projects. It is a

step in the right direction to improve your contractor's results and safer markings in general. NOTE: This language is not intended to define

criteria for marking maintenance. Also, if you're painting every six months or more often, the use of Type I glass is required; this should be the

rare exception among your markings (e.g. centerlines, lead on lines at very busy airports).

2) TT-B-1325D, Type III

- What Changed - Added the following performance criteria: "[When applying Type III] initial readings should yield at least 600 mcd/m²/lux

on white markings and at least 300 mcd/m²/lux on yellow markings at installation". Added that Type III shall be used when a higher reflective

value is desired.

- The Intent - To establish measurable performance requirements for Type III reflective markings at installation on new construction projects.

- What It Means To You - This language gives painting contractors performance criteria to meet or exceed on new construction projects. It is a

step in the right direction to improve your contractor's results and safer markings in general. NOTE: This language is not intended to define

criteria for marking maintenance.

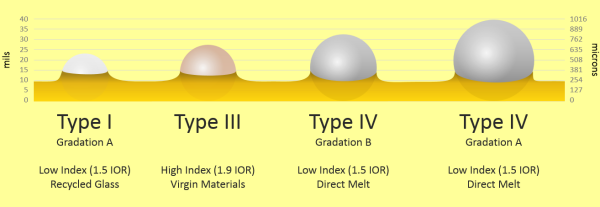

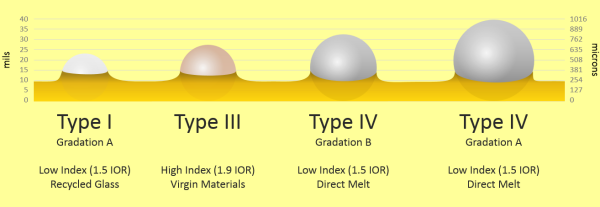

3) TT-B-1325D, Type IV

- What Changed - Added the following language: "Type IV, gradation A shall be used with TT-P-1952E, Type III paint. The glass

beads are larger than either Type I or Type III (see graphic, below), thus requiring more of the coating material to properly anchor. When applied

properly in 25-30 mils wet film thickness (wft) of the high build acrylic waterborne material, reflective readings should yield at least 400

mcd/m²/lux on white markings and at least 225 mdc/m²/lux on yellow markings at installation".

- The Intent - To establish measurable performance requirements for Type IV (gradation A) reflective markings at installation on new

construction projects, and requires this type of glass to be used in concert with a thicker coating.

- What It Means To You - This language gives painting contractors performance criteria to meet or exceed on new construction projects. It

is a step in the right direction to improve your contractor's results and safer markings in general. NOTE: This language is not intended to

define criteria for marking maintenance. I could not agree more with the importance of properly anchoring any bead type in coatings. However,

I do not recommend the use of Type IV, gradation A for use with waterborne paints, and I generally do not advocate the slightly smaller Type IV,

gradation B, largely due to the relative large amount of paint required to achieve optimal bead embedment.

4) Preformed Thermoplastic, 1.5 IOR

- What Changed - Added the following language: "Preformed thermoplastic pavement markings should yield at least 225 mcd/m²/lux on white

markings at installation and at least 100 mcd/m²/lux on yellow markings at installation".

- The Intent - To establish measurable performance requirements specifically for preformed thermoplastic.

- What It Means To You - Minimum reflective values can now be measured when preformed thermoplastic is installed which is a good thing.

However, I am unsure as to why the reflectivity goals are 25% less than those of the Type I bead, listed above. In my opinion, performance criteria

for reflectivity should not be dependent upon material type. A consistent level of performance should be expected of all material types at

installation.

5) Measuring Performance

- What Changed - Added the following language: "Reflective performance must be measured in accordance with ASTM E1710 and with the

practices in ASTM D7585 shall be followed for taking retroreflectivity readings with a portable retro-reflectometer and computing measurement

averages".

- The Intent - Clearly defines what methods are used to measure reflective performance of pavement markings.

- What It Means To You - These methods have been the standard for some time on our highways. One could argue the 30-meter

geometry used by retro-reflectometers may be inadequate for the viewing angles of aircraft, but it's still a great idea to require what

methods we do have available. I recommend Delta's LTL-X, however a new one costs over $20,000. You can always

borrow ours. NOTE: Measuring reflectivity is a best practice to evaluate

current effectiveness, but it does not determine how long the marking will remain effective.

620-3.1 – Weather Limitations

1) Wind Speed

- What Changed - Added the following language: "Markings shall not be applied when the wind speed exceeds 10 mph unless windscreens

are used to shroud the material guns".

- The Intent - To prevent material application to be adversely affected by windy conditions.

- What It Means To You - Since I have never been to an airport that isn't windy... it means you should expect your contractor to at least

have a method of shrouding their material guns in the event the wind starts displacing glass beads. I don't care if they use cardboard and duct

tape, as long as it results in uniform material distribution (this applies to all marking equipment).

Questions? Feel free to contact me directly, I'm happy to help where I can.

Next time we'll be taking a look at the surface preparation guidance (a personal favorite)... until then.

Back to Webletter

|