|

|

Airfield Marking Handbook - Chapter 4By Mike Speidel

This piece is the third in a six article series summarizing each chapter contained within the Handbook. As the principal authors of the Airfield Marking Handbook, we will also be identifying key issues for your consideration.

Surface Preparation Show of hands, please: How many of you have ever had problems with pavement markings in the past? Ok, put your hands down, all of your office mates are looking at you strangely. I'm going to estimate from those of you who confirmed the question that roughly 75% of those past issues can be attributable to a lack of surface preparation. Outside of layout, preparation is the most fundamental flaw in airfield marking installation. If you're marking a surface with anything between paint and pavement, it could represent a potential problem. Chapter 4 addresses the activities and methods associated with surface preparation prior to applying markings to airfield pavement. The types of contaminants that may need to be cleaned off and the methods that can be used to clean them are discussed. Chapter 4 addresses cleaning (preparing) existing markings to improve the bond between the surface and the new marking. This chapter affects everyone involved with markings; the design engineers, applicators, operations staff, and project inspectors.

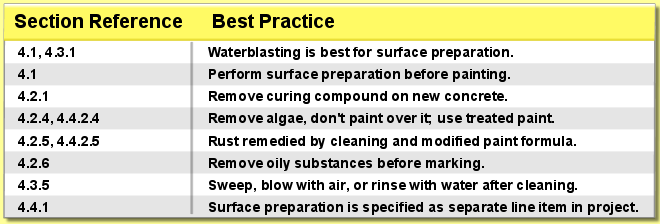

So what is the definition of surface prepartation? Surface preparation is the cleaning and removal of anything that would reduce the bond between a newly applied material and the surface. Preparation is far different from paint removal, although similar equipment can be utilized to complete either operation. Many of the marking failures Sightline investigates are directly related to inadequate surface preparation. Surface preparation should be included as a separate line item in the project specifications. Specifications that are well defined are necessary to communicate expectations to the applicator. They also provide the inspector with the criteria to enforce compliance. It is also a best practice to define what will be the goal of the preparation; whether it be removing curing compound, poorly bonded existing paint, or contaminants such as algae, oils and jet blast, rust staining, rubber deposits, or perhaps just dirt and debris. Waterblasters were determined to be the most appropriate, versatile equipment for use when preparing surfaces for airfield markings. Chapter 4 discusses other methods of preparation such as sandblasting, shotblasting, grinding. However, each of these methods have limitations. Irrespective of what method is specified, areas to be prepared should be followed with sweeping, brooming, or blowing with compressed air to ensure a proper bonding site for new material. Want a handbook? Check this out. If you'd like a free handbook, just sign up for one of our Symposiums; it's the course literature. For details about a seminar in your area, click on this link for information about the Airfield Marking Symposium. |

With the Airfield Marking Handbook hot off the presses and now being distributed to the industry, let's take a look at

what's inside. In each of the next several issues of Sightline's webletter, I'm going to take a look at each chapter and it's

highlights. It's the most comprehensive resource available dealing strictly with airfield markings. To obtain a copy,

With the Airfield Marking Handbook hot off the presses and now being distributed to the industry, let's take a look at

what's inside. In each of the next several issues of Sightline's webletter, I'm going to take a look at each chapter and it's

highlights. It's the most comprehensive resource available dealing strictly with airfield markings. To obtain a copy,