|

|

AIP EligibilityBy Donna SpeidelDuring a recent marking assessment at a medium-size commercial airport, we were struck by the staff's acknowledgment that they had a moderate to severe FOD issue that would only worsen when more paint was applied over the thick and chunky paint. Awareness of the challenge was the first step toward alleviating it. But they didn't have the resources to do it: Challenge No. 2. The FAA understands that FOD is a serious concern for aircraft, as do the Air Force, the Navy and the Marines who conduct FOD walks across ramp areas, taxiways, and runways almost daily so as not to ingest foreign object debris (FOD – nuts, bolts, rocks, chunks of paint) into the engines. Wait - chunks of paint? Seriously?

It happens, more frequently than we know. The airlines pay the freight for the engine repairs because the source of the problem is not as easily detected as it was when the glass beads were ingested. But some airports have been identified as the source of FOD, and have suffered lawsuits to pay damages. It's not that airports want the problem. They'd love to fix it. It's just they don't have the right equipment to do it, and they either don't think it's enough of a problem, the FAA hasn't told them to fix it, or they can't afford either a contractor or the equipment. They're literally caught between a paint chunk and a hard place. Airports need financial assistance to do a better job of maintaining their markings. AIP funding is available to airports to assist with safety-related issues, and yet AIP funding for marking equipment has never been eligible. The Airport Improvement Program Handbook states under Order 5100.38C, Chapter 5, Section 5, Paragraph 541, h, "The basic criteria for eligibility of equipment will be that it is needed to meet a safety requirement at a particular airport." I'm not an AIP guru, but I do understand this makes snowplows, sweeper trucks, friction testing equipment, etc., eligible for AIP funding. AIP funding for marking maintenance equipment is needed, to include:

My bet is airports of every size would agree that thick, peeling markings are a hazard to safety. We already know the FAA Safety Inspectors have demanded airports to remove markings due to their thickness. Most of the airports we have audited have issues with marking FOD and I imagine the airports we haven't been to (yet) do as well. If you believe marking maintenance equipment should be AIP eligible to meet a safety requirement, I'd like to hear from you. |

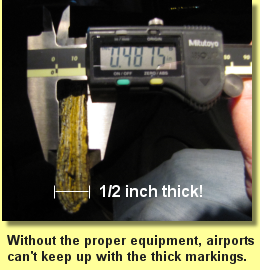

Well, yes. Some years ago, after glass beads were ingested into brand new engines, analyses showed that the glass beads

caused life-cycle damage to the engines. So now imagine a chunk of paint, layer after layer of paint and beads, ingested into an engine,

or lodged into a moving part of an aircraft. To the right, is just one piece of paint we pulled off the main departure runway at a large

US aiport. As the calipers read, 487.5 mils of paint is nearly one half of an inch thick. At the standard coverage rate of waterborne

paint, it would take about 50 applications to become that thick. The Airfield Marking Handbook borrows the Air Force recommendation

of removing markings after FIVE applications. As an industry, we have a serious problem with pavement markings generating FOD and damaging

aircraft.

Well, yes. Some years ago, after glass beads were ingested into brand new engines, analyses showed that the glass beads

caused life-cycle damage to the engines. So now imagine a chunk of paint, layer after layer of paint and beads, ingested into an engine,

or lodged into a moving part of an aircraft. To the right, is just one piece of paint we pulled off the main departure runway at a large

US aiport. As the calipers read, 487.5 mils of paint is nearly one half of an inch thick. At the standard coverage rate of waterborne

paint, it would take about 50 applications to become that thick. The Airfield Marking Handbook borrows the Air Force recommendation

of removing markings after FIVE applications. As an industry, we have a serious problem with pavement markings generating FOD and damaging

aircraft.